Navigating Amazon's Fulfillment by Amazon (FBA) system can be a game-changer for your e-commerce business. However, ensuring your products are correctly labeled is crucial for smooth operations. In FBA, product labels (FNSKU labels) and shipment labels serve distinct purposes. Understanding the differences between these labels can help you avoid costly mistakes and streamline your logistics process. Here's a comprehensive guide to help you distinguish between product labels and shipment labels in FBA.

Understanding the Two Types of Labels

To effectively manage your inventory and shipments within Amazon's FBA system, it's essential to grasp the fundamental differences between product and shipment labels. Both labels play pivotal roles, but they serve unique functions that cater to different aspects of the fulfillment process. To understand their specific purposes and applications, let's delve deeper into each type.

Product Labels (FNSKU Labels)

FNSKU stands for Fulfillment Network Stock Keeping Unit. These labels are unique identifiers Amazon assigns to each product you sell through FBA.

Identification: FNSKU labels are unique to each product, allowing Amazon to track inventory accurately. They typically start with prefixes like "XOO" or "B0" and overlay the product's original barcode.

Application: Each product unit must have an FNSKU label attached to its packaging. This ensures that Amazon can identify and manage each item separately within its vast fulfillment network.

Purpose: The primary role of FNSKU labels is to enable Amazon's system to recognize and track your inventory. This ensures that products are correctly stored, picked, and shipped to customers, maintaining the integrity of your stock.

Shipment Labels

Shipment labels differ from product labels and are used to manage the overall shipment sent to Amazon's warehouses.

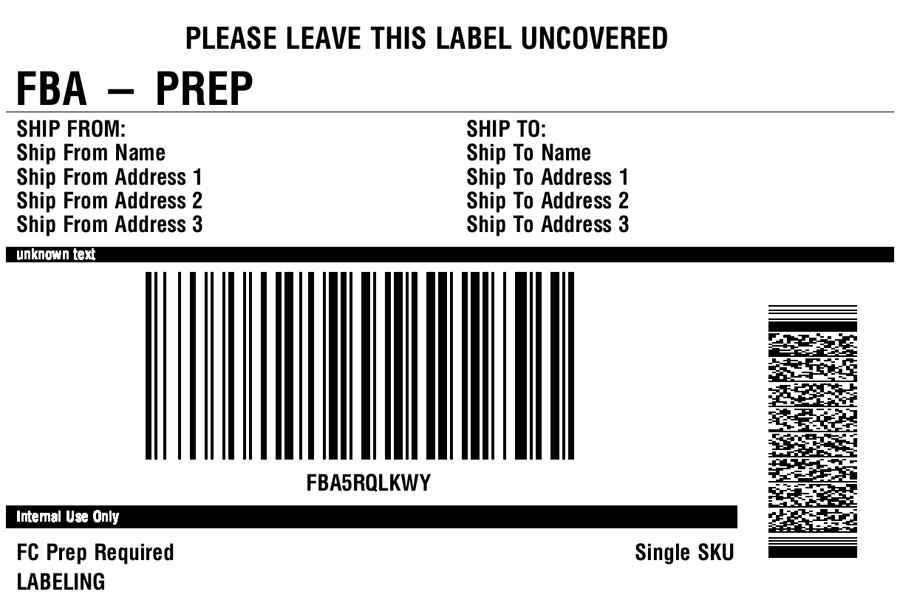

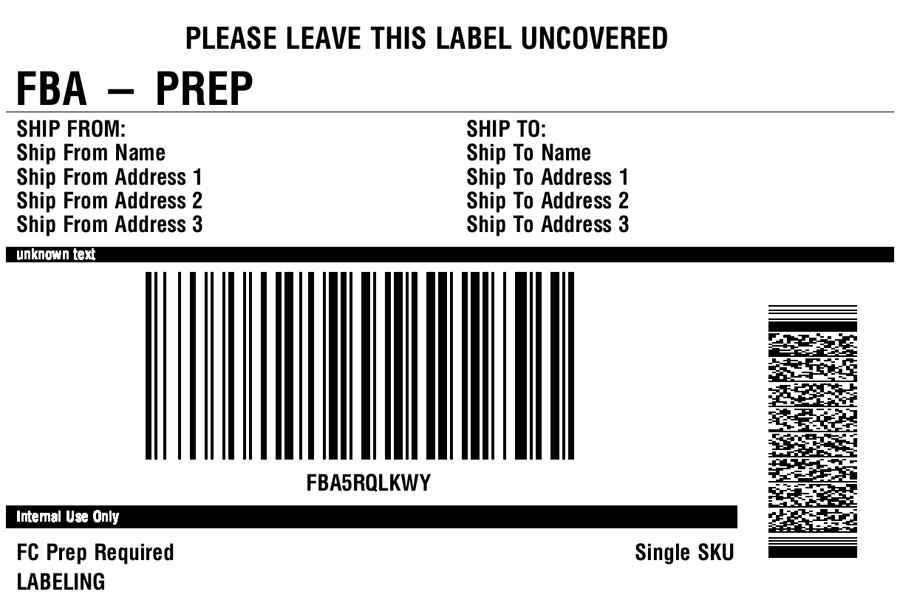

Outer Package Identification: Shipment labels are affixed to the exterior of the boxes you send to Amazon. These labels include a shipment ID (e.g., FBAXXXXXX) and a shipment number.

Multiple Box Identification: If your shipment consists of multiple boxes, each box will have a unique identifier like U001, U002, etc. This helps Amazon distinguish between different boxes within the same shipment.

Purpose: Shipment labels facilitate the efficient handling of your packages upon arrival at Amazon's fulfillment centers. They help warehouse staff quickly verify which shipment the boxes belong to and ensure accurate processing and storage.

Key Differences Between Product Labels and Shipment Labels

Understanding the distinct roles of product and shipment labels is crucial for maintaining an organized and efficient FBA process. Here are the primary differences that set them apart:

Usage Context

Product Labels: These are used for individual product identification within Amazon's inventory system. Each product unit in your shipment must have its own FNSKU label.

Shipment Labels: Used for managing entire shipments and their constituent boxes. These labels are only applied once per box, regardless of the number of products inside.

Application Process

Product Labels: You must print and apply an FNSKU label to every product unit. This requires careful attention to ensure each item is correctly labeled before shipping.

Shipment Labels: Print a shipment label for each box in your shipment. The number of shipment labels corresponds to the number of boxes you send to Amazon.

Visual Identification

Product Labels: Typically smaller and placed directly on the product's packaging, covering the original barcode. They contain the FNSKU code, which is unique to each product.

Shipment Labels: Larger and placed on the outside of the shipping boxes. They include shipment IDs and box numbers, making them easily visible for quick identification.

Practical Scenarios: When to Use Each Label

To ensure your shipments are processed smoothly, knowing when and how to use each type of label effectively is important. Here are some common scenarios:

Single Product Shipment

If you're sending a shipment containing only one type of product, each unit will have an FNSKU label, and each box will have a shipment label. This ensures that both individual products and the overall shipment are properly tracked.

Multiple Product Shipment

Each product unit will still require an FNSKU label for shipments containing different types of products. Additionally, each box will need a shipment label with a unique box number to differentiate between the various products inside.

Printing and Applying Labels

Correctly printing and applying labels is crucial to avoid errors during fulfillment. Here's how to handle each type of label:

Printing Product Labels

Quantity: Print one FNSKU label for each product unit in your shipment.

Quality: Use a high-quality printer to ensure the barcode is clear and scannable. Blurry or smudged labels can lead to scanning errors and inventory issues.

Placement: Place the FNSKU label outside the product's packaging, covering the original barcode if necessary. Ensure it's easily accessible for scanning.

Printing Shipment Labels

Quantity: Print one shipment label for each box in your shipment.

Visibility: Attach the shipment label to a flat surface outside the box. Avoid placing labels on seams or corners where they might be obscured.

Durability: Use durable label paper to withstand handling and transportation without tearing or fading.

Best Practices for Labeling in FBA

Implementing best practices for labeling can significantly enhance the efficiency and accuracy of your FBA operations. Here are some recommendations:

Double-Check Requirements: Always refer to Amazon's latest FBA labeling guidelines to ensure compliance. Requirements may change, and staying updated helps avoid mistakes.

Organize Your Shipment: Clearly label each box and product to streamline the receiving process at Amazon's warehouses. Organized shipments reduce the risk of errors and delays.

Use Labeling Software: Consider using specialized FBA labeling software to automate the process, especially for larger shipments. This can save time and minimize human error.

Test Scannability: Before finalizing your shipment, test the scannability of your labels to ensure Amazon's systems can read them without issues.

Keep Backup Labels: Have spare labels on hand in case of printing errors or damaged labels. This ensures you can quickly replace any problematic labels without disrupting your shipment timeline.

Conclusion

Correctly distinguishing and applying product labels (FNSKU) and shipment labels is essential for a seamless FBA experience. By understanding their differences and following best practices, you can ensure your products are accurately tracked and efficiently processed within Amazon's fulfillment network. Proper labeling prevents inventory errors and enhances your overall logistics efficiency, contributing to better customer satisfaction and business growth.

For more detailed information, always refer to Amazon's FBA Labeling Guidelines and stay updated with any policy changes to maintain compliance and optimize your FBA operations.

2024-06-11

Understanding the Bunker Adjustment Factor (BAF) Surcharge

The Bunker Adjustment Factor (BAF) surcharge is an additional fee levied by shipping companies to offset the volatility in fuel prices. This fee is crucial as it ensures stability in shipping costs despite fluctuations in the price of bunker fuel, which is essential for maritime operations.Definition and PurposeThe Bunker Adjustment Factor, also known as Fuel Adjustment Factor or Bunker Surcharge, is a mechanism designed to mitigate the variations in the cost of ship fuel, commonly referred to as "bunker". BAF serves as the floating part of sea freight charges, allowing shipping companies to adjust their tariffs in response to fluctuations in fuel prices, ensuring that changes in bunker costs do not adversely impact their financial stability.Calculation of BAFThe calculation of BAF is typically based on a straightforward formula: BAF = Fuel Prices x Trade Factor. Here, the trade factor encompasses various elements such as the average fuel consumption for a particular trade, taking into account factors like route, vessel direction, distance, transit time, and the weight of the cargo.Influencing FactorsThe amount of the BAF surcharge depends on several variables, including:Route and Distance: Longer routes and distances usually entail higher fuel consumption, which can result in a higher BAF surcharge.Vessel Direction and Transit Time: Directions and longer transit times requiring more fuel will impact the BAF computation.Weight and Type of Cargo: Heavier cargo and specific types of freight can affect the fuel consumption and, consequently, the BAF.Quarterly AdjustmentsBAF charges are often adjusted quarterly to reflect changes in fuel prices. Historically, these adjustments were standardized by the Transpacific Stabilization Agreement (TSA) using Brent crude oil as a benchmark. However, following the disbanding of the TSA in 2018, ship operators began setting their bunker surcharges independently, under the supervision of the European Commission.Practical Applications and ImpactBy examining trade routes from Asia to Europe and Asia to North America, it has been observed that the practice of applying the BAF effectively cushions ocean carriers from negative impacts due to fuel price fluctuations. This makes the BAF a powerful tool for altering the incentive structure that carriers face, ensuring they can manage operational costs efficiently.Industry Impacts and Future ExpectationsThe implementation of regulations such as the IMO 2020, which mandated a significant reduction in sulphur emissions from 3.5% to 0.5%, has had a considerable impact on BAF calculations. To comply with these regulations, carriers have had to either transition to low-sulphur fuels, install exhaust scrubbers, or apply for waivers, all of which introduce additional costs. As such, the BAF surcharge has had to be recalculated to account for these increased fuel charges, leading to a rise in overall shipping costs.ConclusionIn summary, the Bunker Adjustment Factor surcharge is a vital component of maritime shipping operations. It provides a flexible framework to account for fuel price fluctuations, enabling carriers to stabilize costs and maintain financial viability amidst changing market conditions. As environmental regulations evolve and fuel technologies advance, the BAF will continue to play a crucial role in the global shipping industry.

2025-01-06

How to Tell Product Labels and Shipment Labels Apart in FBA

Navigating Amazon's Fulfillment by Amazon (FBA) system can be a game-changer for your e-commerce business. However, ensuring your products are correctly labeled is crucial for smooth operations. In FBA, product labels (FNSKU labels) and shipment labels serve distinct purposes. Understanding the differences between these labels can help you avoid costly mistakes and streamline your logistics process. Here's a comprehensive guide to help you distinguish between product labels and shipment labels in FBA.Understanding the Two Types of LabelsTo effectively manage your inventory and shipments within Amazon's FBA system, it's essential to grasp the fundamental differences between product and shipment labels. Both labels play pivotal roles, but they serve unique functions that cater to different aspects of the fulfillment process. To understand their specific purposes and applications, let's delve deeper into each type.Product Labels (FNSKU Labels)FNSKU stands for Fulfillment Network Stock Keeping Unit. These labels are unique identifiers Amazon assigns to each product you sell through FBA.Identification: FNSKU labels are unique to each product, allowing Amazon to track inventory accurately. They typically start with prefixes like "XOO" or "B0" and overlay the product's original barcode.Application: Each product unit must have an FNSKU label attached to its packaging. This ensures that Amazon can identify and manage each item separately within its vast fulfillment network.Purpose: The primary role of FNSKU labels is to enable Amazon's system to recognize and track your inventory. This ensures that products are correctly stored, picked, and shipped to customers, maintaining the integrity of your stock.Shipment LabelsShipment labels differ from product labels and are used to manage the overall shipment sent to Amazon's warehouses.Outer Package Identification: Shipment labels are affixed to the exterior of the boxes you send to Amazon. These labels include a shipment ID (e.g., FBAXXXXXX) and a shipment number.Multiple Box Identification: If your shipment consists of multiple boxes, each box will have a unique identifier like U001, U002, etc. This helps Amazon distinguish between different boxes within the same shipment.Purpose: Shipment labels facilitate the efficient handling of your packages upon arrival at Amazon's fulfillment centers. They help warehouse staff quickly verify which shipment the boxes belong to and ensure accurate processing and storage.Key Differences Between Product Labels and Shipment LabelsUnderstanding the distinct roles of product and shipment labels is crucial for maintaining an organized and efficient FBA process. Here are the primary differences that set them apart:Usage ContextProduct Labels: These are used for individual product identification within Amazon's inventory system. Each product unit in your shipment must have its own FNSKU label.Shipment Labels: Used for managing entire shipments and their constituent boxes. These labels are only applied once per box, regardless of the number of products inside.Application ProcessProduct Labels: You must print and apply an FNSKU label to every product unit. This requires careful attention to ensure each item is correctly labeled before shipping.Shipment Labels: Print a shipment label for each box in your shipment. The number of shipment labels corresponds to the number of boxes you send to Amazon.Visual IdentificationProduct Labels: Typically smaller and placed directly on the product's packaging, covering the original barcode. They contain the FNSKU code, which is unique to each product.Shipment Labels: Larger and placed on the outside of the shipping boxes. They include shipment IDs and box numbers, making them easily visible for quick identification.Practical Scenarios: When to Use Each LabelTo ensure your shipments are processed smoothly, knowing when and how to use each type of label effectively is important. Here are some common scenarios:Single Product ShipmentIf you're sending a shipment containing only one type of product, each unit will have an FNSKU label, and each box will have a shipment label. This ensures that both individual products and the overall shipment are properly tracked.Multiple Product ShipmentEach product unit will still require an FNSKU label for shipments containing different types of products. Additionally, each box will need a shipment label with a unique box number to differentiate between the various products inside.Printing and Applying LabelsCorrectly printing and applying labels is crucial to avoid errors during fulfillment. Here's how to handle each type of label:Printing Product LabelsQuantity: Print one FNSKU label for each product unit in your shipment.Quality: Use a high-quality printer to ensure the barcode is clear and scannable. Blurry or smudged labels can lead to scanning errors and inventory issues.Placement: Place the FNSKU label outside the product's packaging, covering the original barcode if necessary. Ensure it's easily accessible for scanning.Printing Shipment LabelsQuantity: Print one shipment label for each box in your shipment.Visibility: Attach the shipment label to a flat surface outside the box. Avoid placing labels on seams or corners where they might be obscured.Durability: Use durable label paper to withstand handling and transportation without tearing or fading.Best Practices for Labeling in FBAImplementing best practices for labeling can significantly enhance the efficiency and accuracy of your FBA operations. Here are some recommendations:Double-Check Requirements: Always refer to Amazon's latest FBA labeling guidelines to ensure compliance. Requirements may change, and staying updated helps avoid mistakes.Organize Your Shipment: Clearly label each box and product to streamline the receiving process at Amazon's warehouses. Organized shipments reduce the risk of errors and delays.Use Labeling Software: Consider using specialized FBA labeling software to automate the process, especially for larger shipments. This can save time and minimize human error.Test Scannability: Before finalizing your shipment, test the scannability of your labels to ensure Amazon's systems can read them without issues.Keep Backup Labels: Have spare labels on hand in case of printing errors or damaged labels. This ensures you can quickly replace any problematic labels without disrupting your shipment timeline.ConclusionCorrectly distinguishing and applying product labels (FNSKU) and shipment labels is essential for a seamless FBA experience. By understanding their differences and following best practices, you can ensure your products are accurately tracked and efficiently processed within Amazon's fulfillment network. Proper labeling prevents inventory errors and enhances your overall logistics efficiency, contributing to better customer satisfaction and business growth.For more detailed information, always refer to Amazon's FBA Labeling Guidelines and stay updated with any policy changes to maintain compliance and optimize your FBA operations.

2024-06-03

The Critical Role of Weight in Shipping Containers

Decoding Shipping Container Weights: Comparing 20-Foot, 40-Foot, and High-Cube OptionsUnderstanding the weight of shipping containers is essential for safe and efficient transportation of goods. Containers vary in weight depending on their size and type. This article outlines the typical weights of the most common containers: 20-foot standard, 40-foot standard, and 40-foot high-cube containers.20-Foot Shipping ContainerA 20-foot shipping container is a staple in global trade due to its versatility and compact size. On average, an empty 20-foot container weighs between 1.8 to 2.2 metric tons, which is approximately 3,970 to 4,850 pounds. More precise figures suggest that a standard 20-foot container weighs around 2,230 kilograms, or 4,916 pounds, when empty. This weight accounts for the container's structure, including its doors and fixtures.40-Foot Shipping ContainerThe 40-foot shipping container is another widely used type, primarily due to its higher capacity compared to the 20-foot container. An empty 40-foot container typically weighs between 3.8 to 4.2 metric tons, equating to approximately 8,340 to 9,260 pounds. Some sources provide a more narrowed range, indicating that the tare weight of a 40-foot container can range from 3,490 to 3,980 kilograms, or 7,700 to 8,775 pounds.40-Foot High Cube ContainerFor cargo that requires additional height, the 40-foot high cube container is an ideal choice. These containers are slightly taller, leading to an increase in weight. Generally, a 40-foot high cube container weighs about 3.9 metric tons, or 3,900 kilograms, equating to 8,598 pounds. The increased weight is a result of the additional metal used in the container's construction to accommodate the extra height.What Is Tare Weight?Tare weight, also known as tare mass or simply tare, is a critical metric in various industries, particularly in shipping and logistics. It refers to the weight of an empty container or packaging material without the goods inside. Understanding tare weight is crucial for accurate weight calculations and regulatory compliance. Definition and ImportanceTare weight is the measure of a container's empty weight and is essential for determining the net weight of the contents within the container by subtracting the tare weight from the gross weight. In the context of a shipping container, for example, tare weight includes the structure, fixtures, and any non-removable components but excludes the cargo.Application in ShippingIn shipping, tare weight allows for the calculation of the net weight of the cargo, which is vital for billing, inventory management, and compliance with transportation regulations. The net weight is calculated as follows:\[ \text{Net Weight} = \text{Gross Weight} - \text{Tare Weight} \]Where:Gross Weight includes the combined weight of the container and its contents (cargo).Net Weight is the weight of the cargo alone without the container.Accurate tare weight measurements are necessary to ensure that the total weight does not exceed the legal limits set by regulatory bodies such as the International Maritime Organization (IMO). This helps in preventing overloading, which could compromise safety and lead to penalties or shipment delays.Examples of Tare Weight Usage1. Maritime Containers: A 20-foot standard shipping container typically has a tare weight of around 2.2 metric tons, while a 40-foot standard container has a tare weight of about 3.8 metric tons.2. Vehicles: In the transportation industry, the tare weight of a vehicle refers to its weight without any cargo or passengers. This is crucial for calculating payload capacity and ensuring that vehicles comply with road weight limits.3. Packaging: In the retail industry, tare weight is used to determine the net weight of products. For instance, a tin of beans might list the net weight as 400 grams, which excludes the weight of the tin itself.Regulatory ComplianceTare weight is an important factor in complying with international shipping regulations. For instance, under the SOLAS (Safety of Life at Sea) regulations, shippers must verify and provide the Verified Gross Mass (VGM) of packed containers before loading them onto ships . The VGM includes the tare weight of the container plus the weight of the cargo, ensuring that ships are safely loaded.ConclusionThe weight of common shipping containers varies by size and type: a 20-foot container weighs between 1.8 to 2.2 metric tons, a 40-foot container weighs 3.8 to 4.2 metric tons, and a 40-foot high cube container weighs around 3.9 metric tons. Understanding these weights is indispensable for safe shipping practices and regulatory compliance.By keeping these details in mind, shippers can ensure they optimize their loads while adhering to safety standards and regulations, thereby minimizing risks and enhancing the efficiency of their logistics operations.